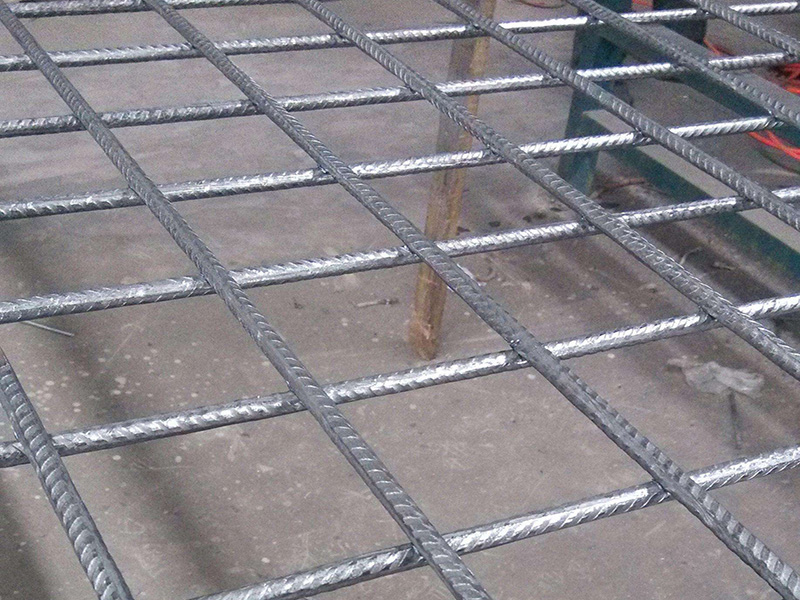

Product Name: Building Steel Mesh

Email:407080001@qq.com

Building steel mesh is a type of building mesh, which is a mesh steel product formed by resistance spot welding of longitudinal and transverse steel bars of the same or different diameters using precision automated machinery. Building steel mesh is a new, efficient, energy-saving, and reinforced concrete structure building material. This mesh is widely used in the modern construction industry, replacing most of the previous manual binding of steel bars on site.

Building steel mesh can be divided into cold-rolled ribbed steel mesh, cold-rolled round steel mesh, and hot-rolled ribbed steel mesh according to raw materials. Among them, cold-rolled ribbed steel mesh is widely used. Building steel mesh is divided into two types based on the grade, diameter, length, and spacing of the steel bars: fixed steel mesh and customized steel mesh.

Characteristics of building steel mesh:

Building steel mesh has the characteristics of strong welding, strong prestressing, and strong corrosion and oxidation resistance; More effective in improving engineering quality and simplifying construction; The characteristics include shortening the working period, saving 33% of steel, reducing cost by 30%, and improving efficiency by 75%.

Usage:

Building steel mesh is mainly used for various reinforced concrete structural projects such as bridges, highways, tunnel backings, high-rise floors, subway culverts, power plant projects, dam foundations, port terminals, river embankment protective walls, airport runways, etc.

Advantages of building steel mesh:

1. Building steel mesh can ensure project quality:

The construction steel mesh is manufactured by a fully automatic and intelligent production line under strict quality control in the factory. The grid size, steel bar specifications, and quality are all strictly controlled. Avoiding the omission of manual tying net. The tying part is sturdy. The occurrence of errors and cutting corners in the production process. Its mesh has high rigidity, good elasticity, uniform and accurate spacing, and high welding point strength. Therefore, it greatly improves the quality of the project.

2. Building steel mesh can improve seismic and crack resistance performance

The longitudinal and transverse bars of the building steel mesh form a mesh structure, which has good bonding and anchoring properties with concrete. The load it bears is evenly distributed, significantly improving the seismic cracking performance of reinforced concrete structures. According to actual tests, laying steel reinforcement mesh on roads can reduce the occurrence of cracks by more than 75% compared to manually tying the mesh.

3. Building steel mesh saves steel usage

The design strength value of widely used circular steel bars is 210N/mm2, while the design strength of building steel mesh is 360N/mm2. Based on the principle of equal strength replacement and considering comprehensive factors, using building steel mesh can save more than 30% of steel bar usage. And the steel mesh needs to be processed after being transported to the construction site, so there is no loss.

4. Building steel mesh can accelerate construction progress

The use of building steel mesh can make construction faster. As long as the welded steel mesh is laid according to the requirements, concrete can be poured, eliminating the need for on-site cutting, placement, and binding of steel bars. Steel mesh can save 50% to 70% of working hours, greatly accelerating construction progress and shortening construction cycles.

PRODUCT PHOTOS

Why Choose Us

Competitive Price - Our mature supply chain system, excellent equipment and technology ensure that our products are highly competitive in terms of cost and price.

Superior Quality - Quality supervision on whole process of production from raw materials, manufacturing, packaging, warehousing till container loading.

On-Time Delivery - The mature logistics management system and company self owned freight forwarder ensure that our OTD rate reaches 95%.

Hot Tags: Small axis net, guardrail net, zinc steel lawn fence, diamond net, embossed net, hook net, and steel grating